High Quality Full Automatic Paper Cup Making Machine with CE certification

$12,000.00

CompareAvailable Options

| Quantity | Model Number | Price | |

|---|---|---|---|

| YG-750 | $12,000.00 |

Automatic Paper Cup Paper Bowl Making Machine Plastic Bowl Plastic Cup Injection Molding Forming Machine

Yugong paper bowl/ cup machine is the automatic environmental machine with multi-running positions. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom-punching, heating, rolling, rimming, rounding and tripping. It is an idea equipment of producing drinking cup, ice-cream cup and other food cone-shaping containers.

Characteristic:

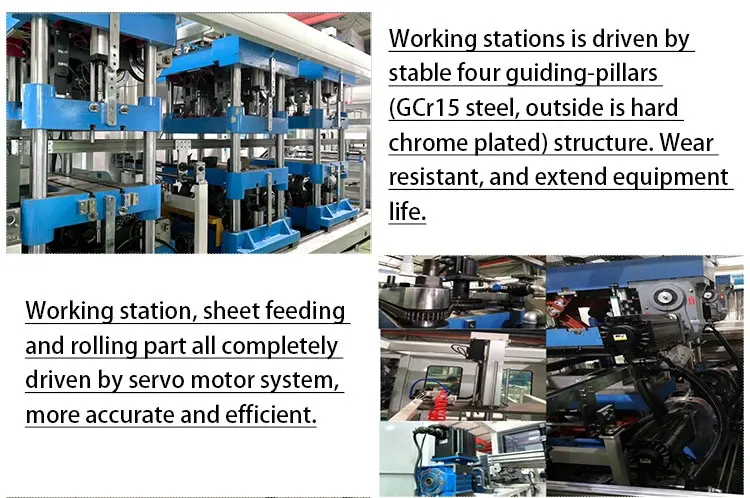

Intelligent Paper Cup Jacket Machine adopts open-type,intermittent division design,gear drive,longitudinal axis design,so they can reasonably distribute each part function.The whole machine adopts spray lubrication.PLC system controls the whole cups forming process.By adopting photoelectric failure-detecting system and servo control feeding,our machine’s reliable performance is guaranteed,thus offering a rapid and stable operation.The maximum speed can reach 100pcs/min,and it is suitable for producing cup jacket forming which is widely used in milk-tea cup,coffee cup,ripple cups,noodle bowl and so on.

Features:

1. High efficiency, energy saving, safety and environmental protection, high qualified rate of finished products.

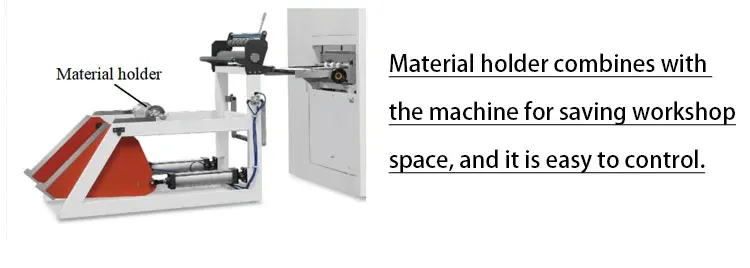

2. The whole machine integrates sheet feeding, heating, stretching, forming, trimming, cup blowing, and waste rewinding at one time, which greatly saves labor costs and increases product profits.

3. The advantages of stable operation, low noise, strong clamping force and high yield.

4. The whole machine is controlled by PLC touch screen, and the operation is simple and convenient. , The cam runs smoothly, sturdy and durable, and the production speed is fast. Different plastic products can be produced by installing different molds to achieve the purpose of one machine with multiple uses.

Parameter:

| Mould Driving Method | Cam |

| Approximate Max. Forming Area | 660 x 300 mm |

| Approx. Running Speed | 15-30 Stroke / min approx. during production |

| Approx. Sheet width required for feeding | 500 – 660 mm in rolls. |

| Mode of cutting arrangement | In mould automatic |

|

Sheet thickness Range |

0.20 – 2.0 mm |

| Material | PP, PS, PET, PVC,PLA |

|

Max. Draw depth, i.e. cup length |

140 mm (Could be special design) |

| Oil Pump Motor Power |

11KW, 6P |

| Sheet Feeding Motor | 2.2KW |

| Max. Sheet roll diameter | 800 mm |

|

Heating arrangement |

Top + bottom heating with IR Ceramic Heater(120pieces, 650W) |

| Temperature Controller & Thermocouple | PID K-Type |

| Type of Mould | Multi cavity 1 – 3 row. |

| Approx. Electrical Consumption | 45KW/hr |

| Approximate Dimension | L3100×W1500×H2500 (mm) |

| Approximate Weight | 4000Kg |

This machine is mainly used to produce disposable plastic containers: such as water cups, beverage cups, jelly cups, yogurt cups, packing bowls, instant noodle bowls, plastic cup lids, square boxes, fruit trays and medicine, light industry, textiles, tourism, toys And other plastic packaging products.

The raw materials are suitable for a wide range, such as PS, PP, PVC, PET, ABS and other plastic sheets can be processed.

| Weight | 6500 kg |

|---|---|

| Dimensions | 450 × 160 × 250 cm |

| Model Number | YG-750 |

Based on 0 reviews

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.